Ultrapak machines are suitable for the production of nonwoven & jute bags in various sizes and designs. Depending on customer needs, the most suitable model can be selected from machines equipped with ultrasonic welding systems, automatic cutting, and assembly features.

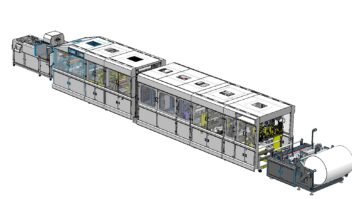

Hunter XC550

Ultrapak > Hunter XC550

Efficient Production, High Performance

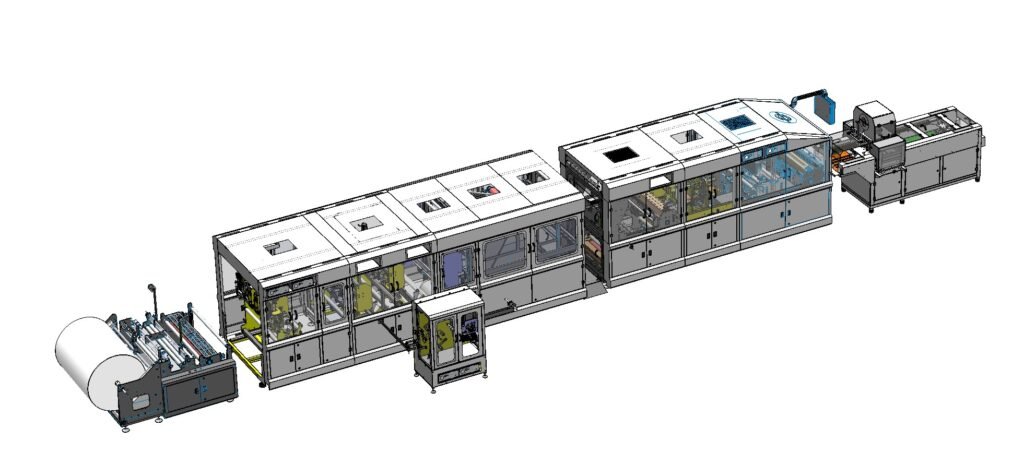

With its user-friendly interface and software featuring advanced algorithms, the Hunter XC 550 series provides maximum stability and efficient production performance through real-time data analysis, speed control, tension management, and precise positioning.

Equipped with an advanced algorithm-based software, the Hunter XC 550 Nonwoven Bag Production Line offers a 30-40% higher performance and continuous bag production capability compared to its competitors.

The Hunter XC 550 Nonwoven Bag Production Line features capabilities that allow for rapid return on investment (ROI) and significantly reduced operational expenses (OPEX). Its high-capacity stable working speed and efficient production capabilities lower per-unit bag production costs, while reduced operational times and improved production efficiency increase business profitability.

Key Features

Hunter XC550, its groundbreaking key features, will take your company a step ahead in the industry.

- Professional maintenance and technical support services,

- Fast, stable, and efficient production,

- Remote access and management support,

- The ability to remotely monitor data,

- Efficient production with a single operator

- Professional maintenance and technical support services,

- High-quality spare parts and easy availability,

- Advanced algorithm-based software infrastructure

- The robust, durable modular design infrastructure offers optional features, enabling the line to be developed with additional modules and functionalities to be enhanced later.

Hunter XC550 Introduction Video

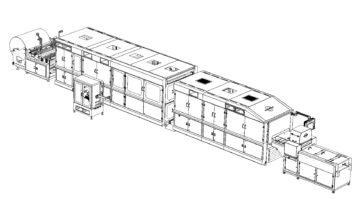

Technical Specifications

TECHNICAL SPECIFICATIONS (*) | |||

FEATURES | HXC 550 | HXC 550 | HXC 550 |

Roll Width | 1400 mm | 1400 mm | 1400 mm |

Roll Diameter | 1100 mm | 1100 mm | 1100 mm |

Bag Width | 250-700 mm | 250-700 mm | 250-700 mm |

Bag Height | 250-700 mm | 350-700 mm | 350-700 mm |

Handle Height | 300-700 mm | 300-700 mm | 300-700 mm |

Handle Width | 25-30 mm | 25-30 mm | 25-30 mm |

Nominal Gusset Width (****) | 100 (total 200) mm | 100 (total 200) mm | 100 (total 200) mm |

Bag Production Speed | 30-110 items/minute | 30-110 items/minute | 30-110 item/minute |

Power Supply | 380 VAC 50Hz kw | 380 VAC 50Hz kw | 380 VAC 50Hz kw |

Total Installed Power | 21 kw | 27 kw | 32 kw |

Pneumatic Consumption (Per Bag) | 1,01 lt/minute | 3,01 lt/minute | 3,01 lt/minute |

Pneumatic Pressure | 6 Bar | 6 Bar | 6 Bar |

Total Machine Weight* | 8.600 kg | 11.100 kg | 12.100 kg |

Machine Dimensions (W x H x L) [mm] * | 2100 x 2100 x 10500 (***) | 2100 x 2100 x 16500 (***) | 2100 x 2100 x 17000 (***) |

Overall Dimensions (W x H x L) [mm]) | 2600 x 2100 x 15500 (**) | 2600 x 2100 x 21500 (**) | 2600 x 2100 x 22000 (**) |

* Net Machine Dimensions (Excluding Electrical Panel)

** Gross Secured Area

***

-Optional Gusset: The gusset can be made 150+150 mm (total 300 mm) optionally.

-The software of our machines can always be updated. For machines with remote access (Internet connection), the software is updated and always trackable.

-In necessary cases, error and downtime analyses are carried out via online connection by us.

-Due to the modular nature of our machines, they can produce bags in a wide range of models and features.

-The production speeds of our machines can be increased or decreased during operation.

-Visual markings and electromechanical devices provide protection on the machine according to ISG regulations.

-All of our machines are CE compliant and have certifications from independent third-party institutions.

Options and Models

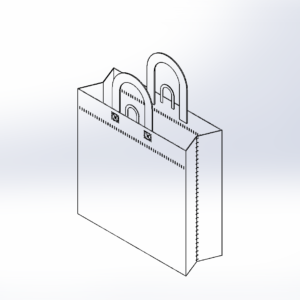

| Handle Type Options | Bag Model Options |

| Net Handle / Award-Winning Handle | Flat & Gussetless |

| Standard | Side Gusseted |

| El geçme | Side Gusseted & Hexagonal |

| Mini Handle | Alt Körüklü & Yan Körüklü |

| Double Handle | |

| Atlet tipi |

Sample Products

Frequently Asked Questions

In this section, you can find answers to frequently asked questions by our customers about our product.

01. Which machines should I use for nonwoven bag production?

02. Are our machines modular?

Yes, our machines have a modular structure. For example, the HUNTER XC 700 Nonwoven Fully Automatic Open Handle Bag Production Line is designed to produce bags in various models and sizes using laminated and non-laminated nonwoven/jute fabric ranging from 30g/m² to 120g/m². Our standard handle machines consist of 8 units, which can be expanded up to 10 units with additional modules.

03. Can I test the machines before purchasing?

Yes, we offer our customers the opportunity to see and test our machines on-site. For more details, please contact us.

04. Contact us, let us assist you!

For detailed information about our products, services, and pricing, feel free to contact us through our communication channels. Our expert team is here to answer all your questions and provide you with the best solutions!

- Email: destek@ultrapak.com.tr

- Phone: +90 (212) 577 22 77

- Address: Akçaburgaz Mahallesi, 3065. Sokak No:2/14, P.K: 34522, Esenyurt / Istanbul

We are here to maximize your satisfaction!