About Us

Transforming the Future with Innovation and Engineering!

Since 2004, our company has been conducting R&D on nonwoven bag production lines within the group. Since 2017, we have started commercial activities and have been offering innovative solutions to the market with ultrasonic welding technology and fully automated systems. With our high-tech production approach, we aim to reduce dependency on foreign technologies and bring domestic and national machines to our country.

Through the machines we have developed and our integrated ultrasonic welding technology, we are setting the global standards of the industry by enabling high-quality and efficient production. Today, the Avcıpak group, with over 80 national and international patents, offers solutions that enhance competitiveness with its innovation-driven approach.

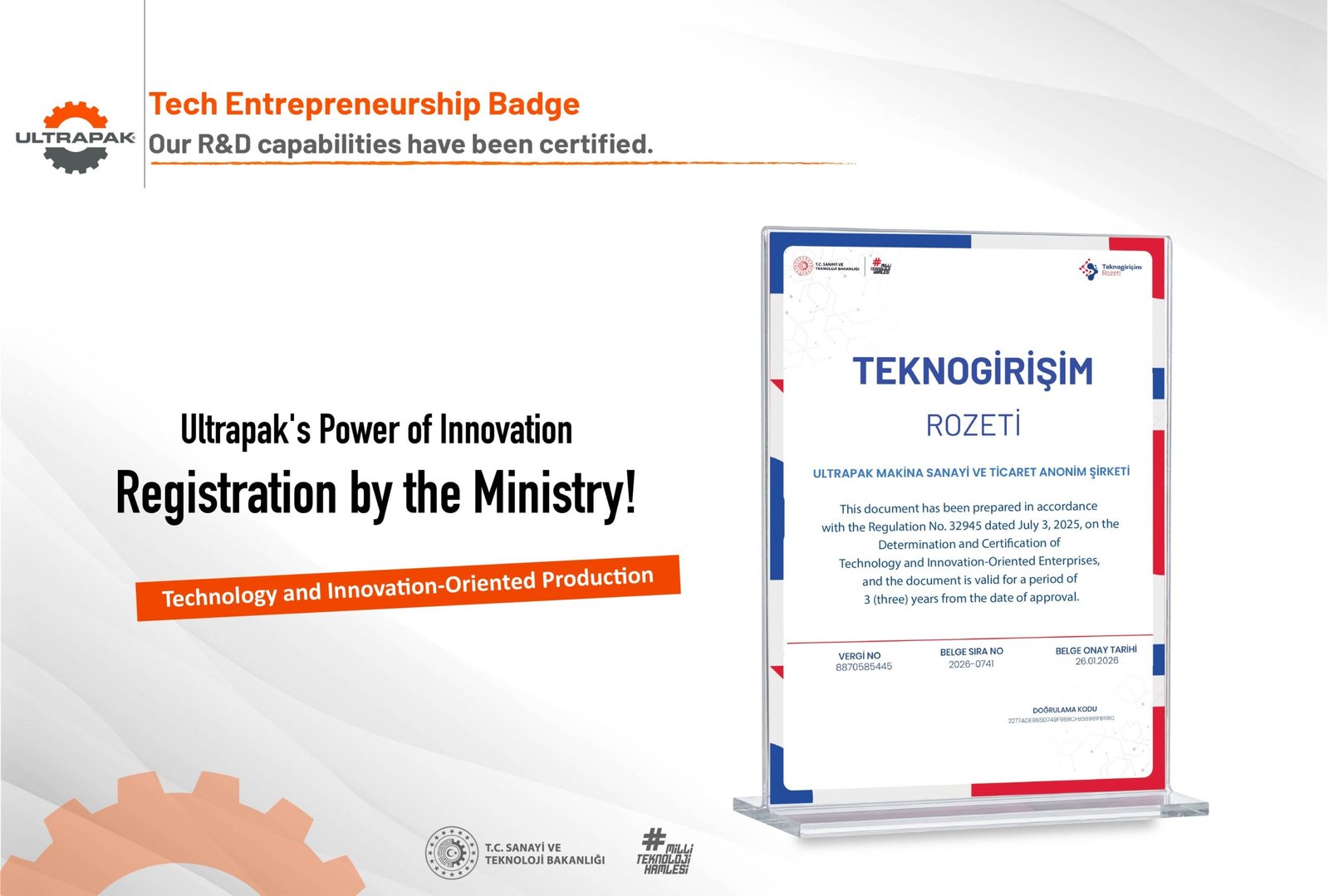

In line with our vision based on R&D and innovation, we have been officially registered as an R&D Center approved by the Ministry of Industry and Technology in 2023. At this center, we aim to lead the future of the industry by developing advanced engineering techniques and next-generation production technologies.

Among our primary goals is to commercialize our patents and utility models to introduce innovative production technologies to the industry. At the same time, we aim to make Turkey a globally competitive manufacturing hub by offering alternative solutions to the issues faced in the logistics and quality sectors of the Far East market.

Moreover, one of our greatest missions is to contribute to the transformation of Turkey from a technology-importing country to one that produces and exports advanced technologies.

Innovation Leading the Industry

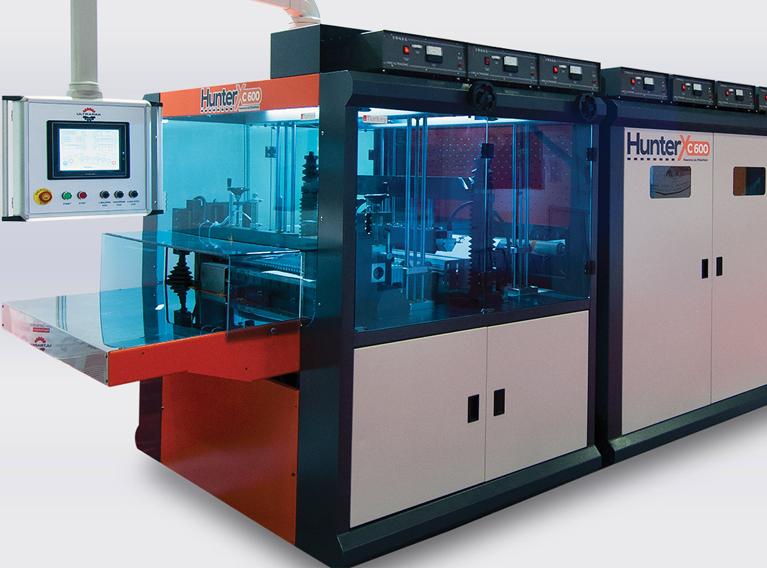

Ultrapak embarked on its journey with the goal of producing nonwoven carrying bags using ultrasonic welding technology, and has reinforced its leading position in the industry with its successful results. Our company, which produced Turkey’s first locally made nonwoven carrying bag cutting machine, continues to grow with its R&D efforts and innovative production approach tailored to customer needs.

Nonwoven fabric is an eco-friendly packaging material, thanks to its recyclable and reusable features. Ultrasonic welding technology contributes to sustainable production processes by offering strong weld strength and serial production advantages. By combining these two important elements, the machines we have developed lead the way in shaping the future of packaging solutions.

At Ultrapak, we do not limit our production to only PP nonwoven material; we also develop machines suitable for PP woven and various film types.

Industry Leadership with the R&D Center

Our company has gained significant momentum in marketing innovations in the industry by strategically focusing on R&D investments. This has enabled us to discover previously unexplored market dynamics, develop production processes for innovative products such as nonwoven bags much earlier than our competitors, and solidify our leadership position in the technical field.

The importance we place on intellectual property rights aims not only to provide legal protection but also to develop creative solutions. By supporting the creative ideas of our employees, we integrate these ideas into our projects and create innovative solutions. We keep sustainability at the forefront at every stage, ensuring we do not forget our environmental and social responsibilities. In this context, we shape both our business processes and products with a forward-looking vision, aiming to contribute to a better world for all our stakeholders.

Our R&D strength, sustainability-focused approach, and continuous innovation mindset are the key factors that distinguish our company from its competitors in the industry. This strong foundation maximizes the potential of our employees and contributes to building a greener and more sustainable future globally.

Mission

As Ultrapak, we lead our industry with advanced engineering, innovation, and sustainable production technologies. With our patented solutions and R&D strength, we develop high-quality and efficient production machines, offering our customers innovative, reliable, and eco-friendly solutions. Our ultimate goal is to transform Turkey into a technology-producing and exporting country.

Vision

Aiming to become a global leader in ultrasonic welding technology, Ultrapak is making a difference in the global market with its innovative and sustainable production approach. With eco-friendly packaging solutions and highly efficient production machines, we will continue to shape the production technologies of the future today as a leading and reliable brand in the industry.

Our Work

Netpak was founded in 1983 in Kayseri Organized Industrial Zone.

In 2002, it began producing eco-friendly, reusable nonwoven bags. In 2003, the company relocated from Kayseri to Istanbul.

Ultrapak was founded, and R&D studies were initiated for the use of ultrasonic welding technology in nonwoven bags.

2008 – A patent application was filed for ultrasonic-welded nonwoven bags. Membership in ASD was acquired.

A printing and lamination production machine project was developed on the same line. PAGEV membership was acquired.

In 2014, the company moved to a new facility. The Istanbul Chamber of Industry’s Environmental and Energy Awards 2025 and the Ministry of Science, Industry, and Technology of the Republic of Turkey’s Efficiency Project Award 2015 were received.

In 2017, the company was ranked among the top 100 fastest-growing companies in Turkey.

- 2018 Istanbul Chamber of Industry Environmental and Energy Awards

- 2018 Turkey Exporters Assembly Most Environmentally Friendly Champion

- 2018 Turkey Packaging Manufacturers Association Packaging Ayyıldızları Award

- 2019 World Packaging Award (World Star)

- 2019 TET Project Market Smart Buildings Environmental 3rd Prize

- 2020 Packaging Ayyıldızları – Competency Award

- 2020 Asia Star Winner in the Eco-Friendly Packaging Category

One of our greatest goals is to contribute to Turkey’s transition from a technology-importing country to one that produces and exports advanced technologies. We continue to work in line with our principles of innovation, quality, and sustainability.

Netpak was founded in 1983 in Kayseri Organized Industrial Zone.

In 2002, it began producing eco-friendly, reusable nonwoven bags. In 2003, the company relocated from Kayseri to Istanbul.

Ultrapak was founded, and R&D studies were initiated for the use of ultrasonic welding technology in nonwoven bags.

2008 – A patent application was filed for ultrasonic-welded nonwoven bags. Membership in ASD was acquired.

A printing and lamination production machine project was developed on the same line. PAGEV membership was acquired.

In 2014, the company moved to a new facility. The Istanbul Chamber of Industry’s Environmental and Energy Awards 2025 and the Ministry of Science, Industry, and Technology of the Republic of Turkey’s Efficiency Project Award 2015 were received.

In 2017, the company was ranked among the top 100 fastest-growing companies in Turkey.

- 2018 Istanbul Chamber of Industry Environmental and Energy Awards

- 2018 Turkey Exporters Assembly Most Environmentally Friendly Champion

- 2018 Turkey Packaging Manufacturers Association Packaging Ayyıldızları Award

- 2019 World Packaging Award (World Star)

- 2019 TET Project Market Smart Buildings Environmental 3rd Prize

- 2020 Packaging Ayyıldızları – Competency Award

- 2020 Asia Star Winner in the Eco-Friendly Packaging Category

One of our greatest goals is to contribute to Turkey’s transition from a technology-importing country to one that produces and exports advanced technologies. We continue to work in line with our principles of innovation, quality, and sustainability.

Executive Management

Ali Avcı

Chairman of the Board

Ali Avcı

Chairman of the BoardÖzgür Avcı

Vice Chairman of the Board

Özgür Avcı

Vice Chairman of the BoardÖzge Avcı Paşaoğlu

Vice Chairman of the Board

Özge Avcı Paşaoğlu

Vice Chairman of the BoardAvcıpak Group

"Avcıpak Group" Headquarter

"Ultrapak & Netpak" Hadımköy Factory

After-Sales Support

Excellence in Engineering

Ultrapak

Innovation and Continuous Improvement

Ultrapak

Solution-Oriented Service

Ultrapak

Press & Blog Contents

Bag Cutting and Sealing Machines: A Guide to Choosing the Right Equipment

- By Ultrapak

- Apr 2, 2025

The Nonwoven Bag Production Process: Key Stages and What to Watch For

- By Ultrapak

- Apr 2, 2025

An Alternative to Plastic Bags: Why Nonwoven Bag Production Matters

- By Ultrapak

- Apr 2, 2025

How Are Fabric and Cloth Bags Made? Key Considerations When Choosing the Right Machine

- By Ultrapak

- Apr 2, 2025